Retouching putty epoxi-stick metal

Retouching putty epoxi-stick metal high temperatur

RETCHPUTY-(EPOXI STICK)-ME-120G

Register now and access our wide range of products

Easy to use

- No laborious mixing process required

- Optimal dosage selection

- Quick to apply

Excellent adhesive properties

- High strength

- Broad range of applications

Simple to process further

- Suitable for a wide range of post-processing options, such as drilling, milling, sawing and sanding

- Can be painted over

High temperature resistance up to 120°C, briefly up to 150°C

Protect from frost and direct sunlight when not applied. Gloves should be worn when applying the repair compound. Due to the different material densities, there are differences in the information regarding the weight of each stick type. For applications subject to high material stresses, the suitability of the repair compound must be checked with preliminary testing.

The usage instructions are recommendations based on the tests we have conducted and our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee consistent quality of our products. We reserve the right to make technical changes and further develop products.

Datasheets(X)

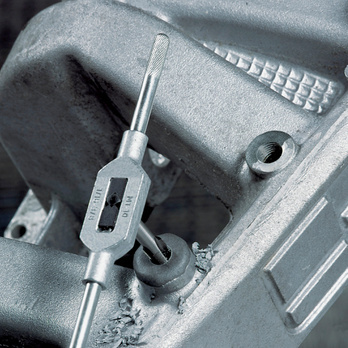

For filling surface damage to metal, e.g. gear unit housing, aluminium and die-cast parts etc.

Application surfaces: Steel (plain and anodised), zinc sheets, cast iron, aluminium, copper, brass, chrome, titanium, lead and stainless steel

- The surface must be clean, dry, free of grease, fuel and oil and must be sufficiently stable

- Roughening the surface beforehand improves adhesion

- Twist or cut off the required quantity and knead with your fingers until an even colour is achieved

- Then apply the repair compound within the next 2 to 3 min

- Dampen your hands with water to improve the modelling process

- After another approx. 20 min, the compound is completely hardened and can be processed further

- For more information, please refer to the technical data sheet

Chemical basis | Epoxy resin |

Colour | Silver coloured |

Density | 2.5 g/cm³ |

Length | 175 mm |

Diameter (Ø) | 22 mm |

Min./max. processing time | 2-5 min |

Can be further processed after min. | 20 min |

Further processing conditions | at 20°C |

Min. final strength | 3 h |

Conditions for final strength | at 23°C |

Min./max. processing temperature | 5 to 25 °C |

Min./max. temperature resistance of the hardened material | -20 to 120 °C |

Max. short-term temperature resistance | 150 °C |

Substrates with good adhesion | Copper, Brass, Aluminium, Lead, Chrome, Stainless steel, Cast iron, Steel (bare and anodised), Titanium, Zinc sheets |

Shore D hardness | 85 |

Min. tensile strength | 6.4 N/mm² |

Shelf life from production/conditions | 24 Month / frost-free storage area, no exposure to sunlight |