For detailed information, other images and documents, please select individual articles from the following table.

Cold wood glue D3/D4

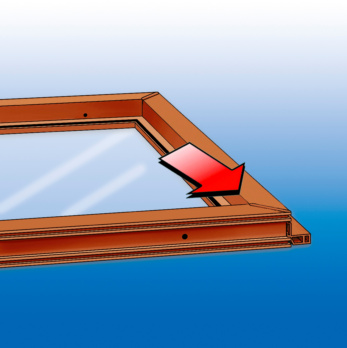

For water-resistant cold bonding on softwood, hardwood and exotic wood, in particular in the production of window frames

Register now and access our wide range of products

Variants

Register now and access our wide range of products

Density 1.09 g/cm3, the product does not contain mineral fillers

A filled product can have a density of up to 1.30 g/cm3

A large amount of glue is applied, so as a filled product for manufacturing, consumption is around 25% higher

In a canister, a filled product occupies 70–75% of the volume, while an unfilled product occupies 90–95%

The colour of the glue is greyish or yellowish in filled products

Filled products tend to leave a grey line of glue

PVA glue with high adhesive power, for indoor gluing

Once the glue has hardened, it becomes semi-transparent without undergoing any discolouration

Strong, elastic adhesive line

With class D4 hardener, in accordance with EN 204/205

- Polyisocyanate-based hardener

- To catalyse D3 glue to D4 class. Add hardener for PVA glues to achieve class D4 resistance to long and frequent exposure to water and atmospheric agents

Compliant with EN 204/205, D3 and WATT 91 standards

Caution with woods containing tannin!

On wood containing high levels of tannin, the glue line may be coloured (chestnut, oak) a problem accentuated by the presence of iron

Protect from frost!

Do not apply below 6/10°C

Gluing at temperatures below 15°C may be ineffective

Storage at temperatures below 5°C and above 35°C can damage the product

With the higher temperatures in the summer months, the open time is significantly reduced

While based on our best experience, the technical advice given should be considered purely as guidance, and must be confirmed through comprehensive practical tests. It does not relieve the purchaser of their responsibility to personally test our products to see whether they are suitable for the intended use

Compliant with EN 204/205, D3 and WATT 91 standards

Recommended where frequent and prolonged exposure to water, condensation and ambient humidity is possible

Suitable for: windows, bathroom cabinets, kitchen cabinets, doors

Hot and cold bonding of softwood, hardwood, resinous wood: fir, pine, poplar, beech, oak, cherry, walnut, chestnut

Solid to particle board and particle board to particle board

Laminates and finishing, hot and cold

External parts must be protected from direct weathering

Mix well before each application. Apply glue evenly with an adhesive applicator roller, brush, dispenser, stainless-steel or plastic notched spreader or a pneumatic spreader. Avoid contact with ferrous materials, which may cause bluish discolorations when in contact with the tannin of the wood. The curing time and bonding speed are influenced by temperature, humidity, porosity of the material and the amount of product used. The best results are obtained under the following conditions: optimal temperature of the product, surface and environment: 18-20 °C; moisture content of wood: 8-12 %. Residues of fresh product can be removed with water, hardened glue can be removed with nitro thinner, acetone or paint cleaner. Apply two coats on solid wood to improve moisture resistance

With hardener

- Creates laminated veneer for under-sink fixtures

- Add 5 % hardener to D3 cold wood glue

- Catalysed D4 cold wood glue has a pot life of 6 hours (at + 20 °C and 60 % humidity). At the end of the service life, any remnant of mixed product cannot be reused and must be disposed of

Open time:

6-8 minutes. This is the maximum time that can elapse between spreading and setting at a temperature of 20 °C (ambient and wood), coating of 150 g/m2, air humidity of 50 % and wood moisture content of 10 %

This time is reduced if:

- Spreading is less than 150 g/m2

- The temperature is above 20 °C

- The air humidity is below 50 %

- The wood moisture content is below 10 %

- If the gluing takes place in environments with particularly hot air currents

It increases if:

- Spreading is more than 150 g/m2

- The temperature is below 20 °C

- The air humidity is above 50 %

- The wood moisture content is above 10 %

Setting time:

- 20-30 minutes. This is the time that the item should be allowed to set at a temperature of 20 °C (ambient and wood), coating of 150 g/m2, air humidity of 50 % and wood moisture content of 10 %

- It is recommended to wait at least 24 hours before further processing

This time is reduced if:

- Spreading is less than 150 g/m2

- The temperature is above 20 °C

- The air humidity is below 50 %

- The wood moisture content is below 10 %

It increases if:

- Spreading is more than 150 g/m2

- The temperature is below 20 °C

- The air humidity is above 50 %

- The wood moisture content is above 10 %

Viscosity:

- Not to be confused with density; it is the product's resistance to flow

- 14,000 ± 1,000 mPas, average

- Do not dilute the product

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!