For detailed information, other images and documents, please select individual articles from the following table.

All-rounder injectable mortar WIT-VM 250

The all-rounder for concrete, masonry and post-installed rebar connections

Register now and access our wide range of products

Variants

Register now and access our wide range of products

- Two-component resin mortar, styrene-free vinyl ester

- Individual fixing point for cracked and uncracked concrete, seismic performance category C1

W-VI-A anchor rod, W-VD-A anchor rod, standard threaded rod with acceptance test certificate 3.1

- Individual fixing point for masonry (system with WIT-SH perforated sleeve):

WIT-SH perforated sleeve, WIT-AS anchor rod, WIT-IG internally threaded sleeve

- Individual fixing point for masonry (system with SH perforated sleeve):

SH perforated sleeve, W-VI-A anchor rod, W-VI-IG internal thread anchor, standard threaded rod with acceptance test certificate 3.1

- Post-installed rebar connection

- European Technical Assessment ETA-12/0164: Individual fixing point + cracked and uncracked concrete (W-VD-A anchor rod, standard threaded rod with 3.1 acceptance test certificate), seismic performance category C1

- European Technical Assessment ETA-13/1040: Individual fixing point + masonry consisting of solid and perforated block, autoclaved aerated concrete (WIT-SH perforated sleeve, WIT-AS anchor rod, WIT-IG internally threaded sleeve, autoclaved aerated concrete only with WIT-SH 18x95 perforated sleeve)

- European Technical Assessment ETA-16/0757 and ETA-20/0854: Individual fixing point + masonry consisting of solid and perforated block, autoclaved aerated concrete (SH perforated sleeve, W-VI-A anchor rod, W-VI-IG internal thread anchor, threaded rod with acceptance test certificate 3.1, autoclaved aerated concrete only without perforated sleeve)

- European Technical Assessment ETA-12/0166: Post-installed rebar connection, 330 ml, 420 ml and 825 ml cartridges only

- EPD: Environmental product declaration in accordance with ISO 14025 and EN 15804+A2, EPD-AWU-20230406-CBA3

We recommend the Würth Technical Software for planning and dimensioning your assembly.

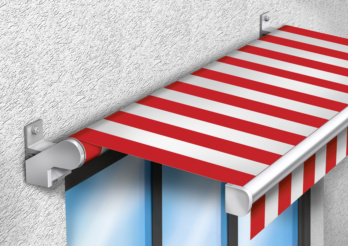

Awning

Awning

Steel supports

Steel supports

Brackets

Brackets

French balconies

French balconies

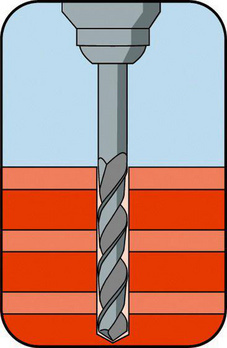

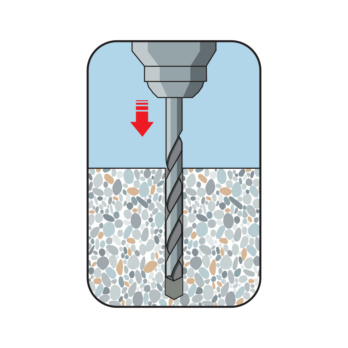

Drill holes with a rotary drill (without impact mechanism)

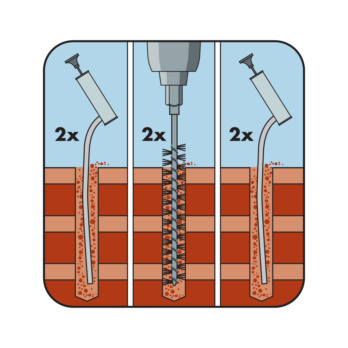

Clean the drill hole:

2x blow out/2x mechanical brush out/2x blow out

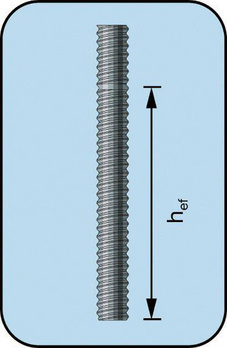

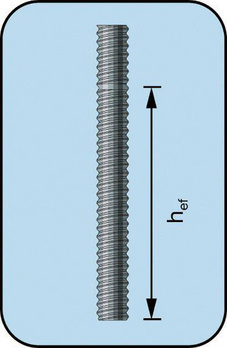

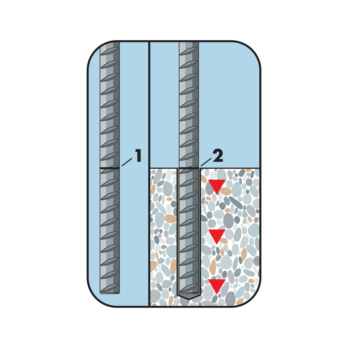

Cut anchor rod to length and mark the desired insertion depths

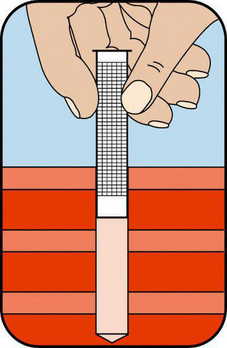

Insert perforated sleeve

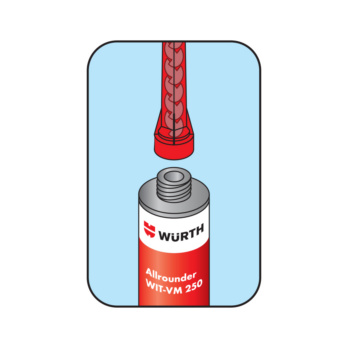

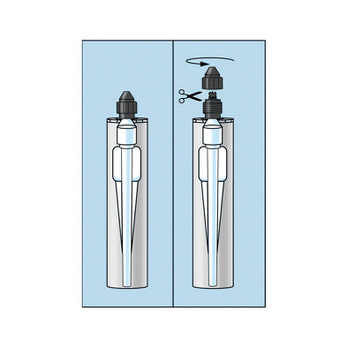

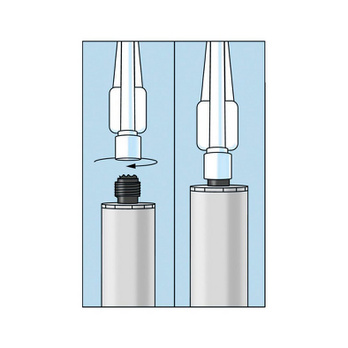

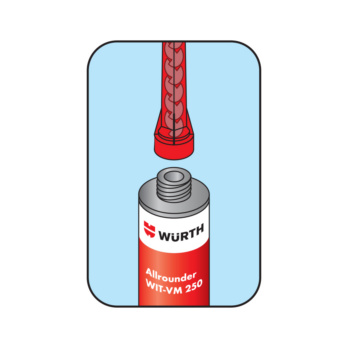

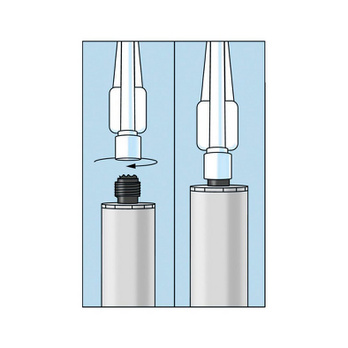

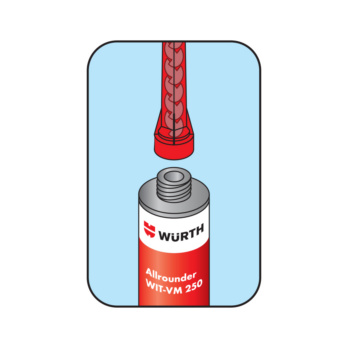

Screw mixer onto cartridge

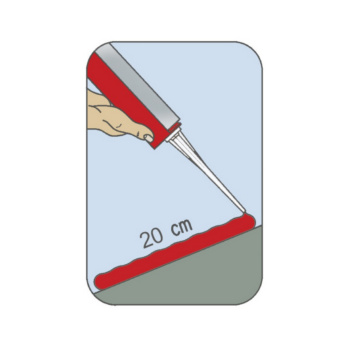

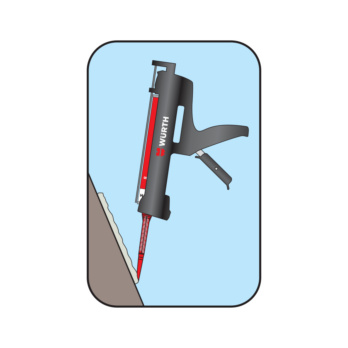

Discard the first section of mortar (until the mortar is uniformly coloured - approx. 10 cm)

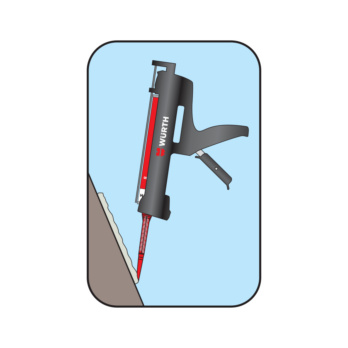

Completely fill with composite mortar from end of perforated sleeve

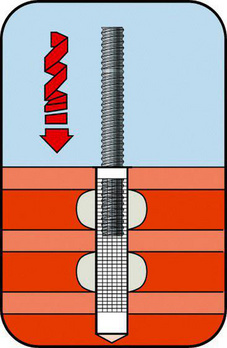

Press in anchor rod up to the bottom of the sleeve while turning slightly

Load can be applied to the reinforcement bar after observing the curing time

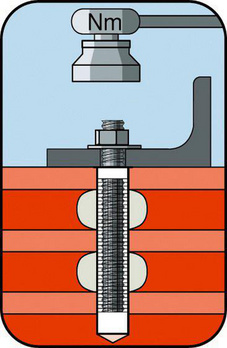

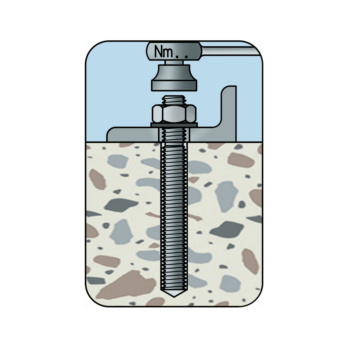

Mount component; do not exceed maximum torque

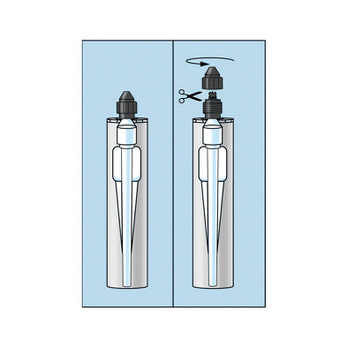

Cut tubular film clip before use!

Screw mixer onto cartridge

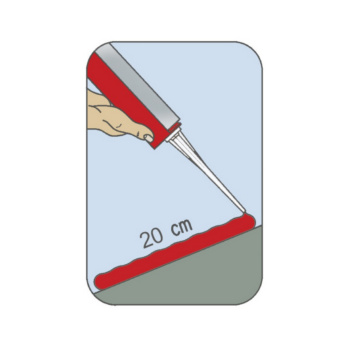

Before use, dispense a bead of approx. 20 cm

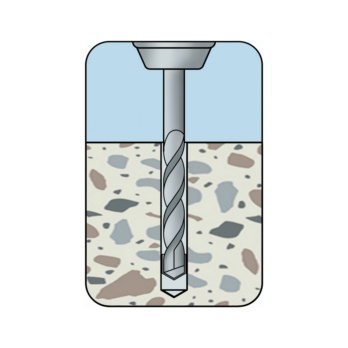

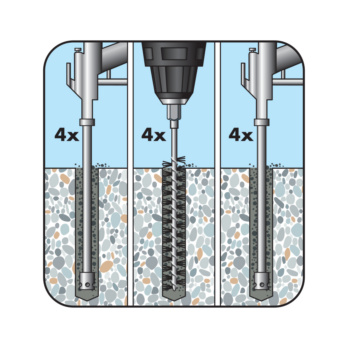

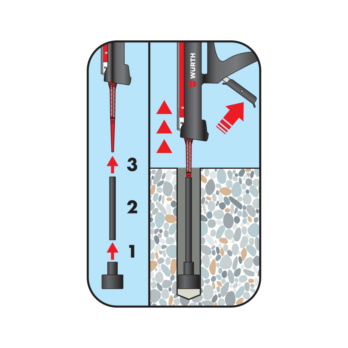

Create the drill hole

Clean the drill hole:

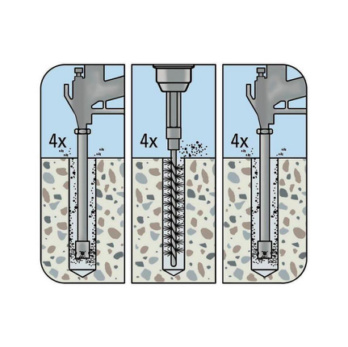

Blow out 4x with compressed air/brush out 4x mechanically/blow out 4x with compressed air

Cut anchor rod to length and mark the desired insertion depths

Screw mixer onto cartridge

Discard the first section of mortar (until the mortar is uniformly coloured - approx. 10 cm)

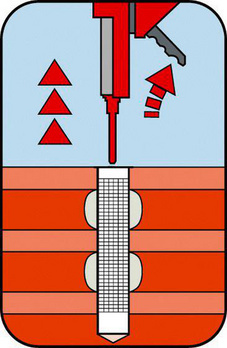

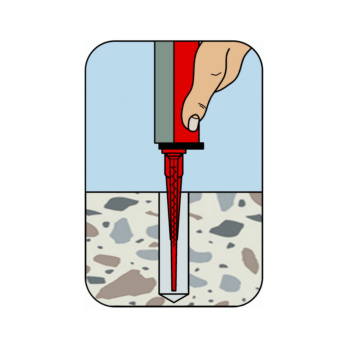

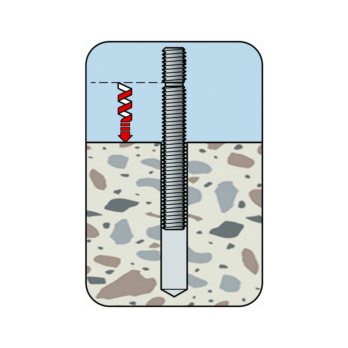

Fill composite mortar from bottom of drill hole

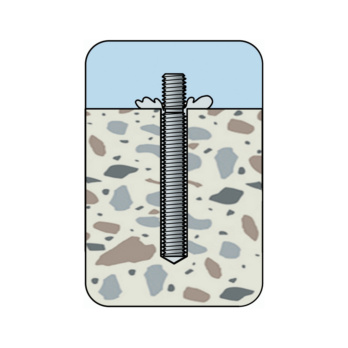

Press in anchoring element up to drill hole base while turning slightly

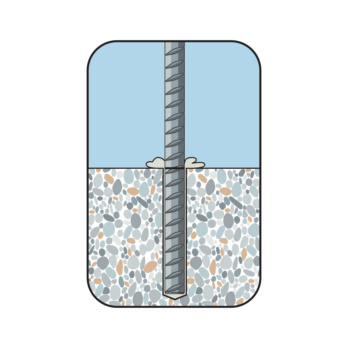

Visual check of mortar volume, embedment depth mark

Load can be applied to the reinforcement bar after observing the curing time

Mount the component. Do not exceed the maximum torque

Cut tubular film clip before use!

Screw mixer onto cartridge

Before use, dispense a bead of approx. 20 cm

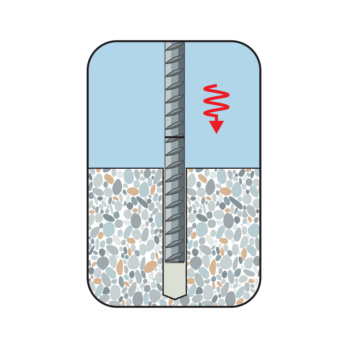

Drill the hole

Clean the drill hole:

Blow out 4x with oil-free compressed air (min. 6 bar)

Brush out 4x mechanically

Blow out 4x with oil-free compressed air (min. 6 bar) (d. <20 mm and d. < 10xds)

Blow out 4x with hand pump, brush out 4x mechanically, blow out 4x with hand pump

Place the embedment depth mark on the rod and check the drilling hole depth

Screw mixer onto cartridge

Discard the first section of mortar (until the mortar is uniformly coloured - approx. 10 cm)

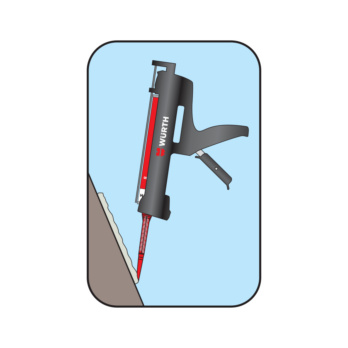

Mount injection equipment, fill composite mortar from bottom of drill hole

Insert the reinforcement bar until it reaches the mark, turning slightly

Visual check of the mortar volume, observe maximum processing time

Load can be applied to the reinforcement bar after observing the curing time

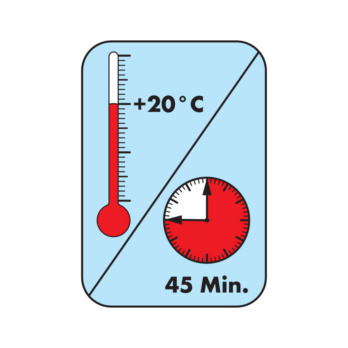

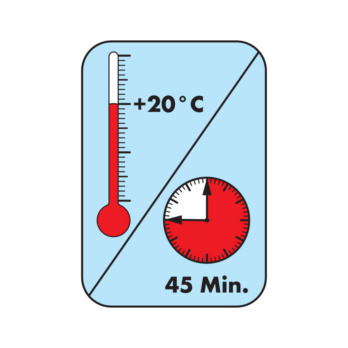

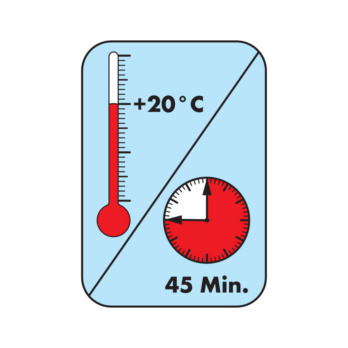

| Minimum curing times in concrete | |||

| Temperature of base material | Processing time | Minimum curing time in dry concrete | Minimum curing time in wet concrete |

| ≥ -10 °C1) | 90 min | 24 h | 48 h |

| ≥ -5 °C2) | 90 min | 14 h | 28 h |

| ≥ 0 °C2) | 45 min | 7 h | 14 h |

| ≥ +5 °C2) | 25 min | 2 h | 4 h |

| ≥ +10 °C2) | 15 min | 80 min | 160 min |

| ≥ +20 °C2) | 6 min | 45 min | 90 min |

| ≥ +30 °C2) | 4 min | 25 min | 50 min |

| ≥ +35 °C2) | 2 min | 20 min | 40 min |

| ≥ +40 °C3) | 1.5 min | 15 min | 30 min |

| 1) Cartridge temperature: ≥ +15 °C 2) Cartridge temperature: +5 °C to +25 °C 3) Cartridge temperature: < 20 °C | |||

| Minimum curing times in masonry | |||

| Temperature of base material | Processing time | Minimum curing time in dry masonry | Minimum curing time in wet masonry |

| -10 °C to -6 °C1) | 90 min | 24 h | 48 h |

| -5 °C to -1 °C2) | 90 min | 14 h | 28 h |

| 0 °C to +4 °C2) | 45 min | 7 h | 14 h |

| +5 °C to +9 °C2) | 25 min | 2 h | 4 h |

| +10 °C to +19 °C2) | 15 min | 80 min | 160 min |

| +20 °C to +24 °C2) | 6 min | 45 min | 90 min |

| +25 °C to +29 °C2) | 4 min | 25 min | 50 min |

| +30 °C to +40 °C3) | 2.5 min | 15 min | 30 min |

| 1) Cartridge temperature: ≥ +15 °C 2) Cartridge temperature: +5 °C to +25 °C 3) Cartridge temperature: < +20 °C | |||

- European Technical Assessment ETA-12/0164: Individual fixing point + cracked and uncracked concrete (W-VD-A anchor rod, standard threaded rod with 3.1 acceptance test certificate), seismic performance category C1

- European Technical Assessment ETA-13/1040: Individual fixing point + masonry consisting of solid and perforated block, autoclaved aerated concrete (WIT-SH perforated sleeve, WIT-AS anchor rod, WIT-IG internally threaded sleeve, autoclaved aerated concrete only with WIT-SH 18x95 perforated sleeve)

- European Technical Assessment ETA-16/0757 and ETA-20/0854: Individual fixing point + masonry consisting of solid and perforated block, autoclaved aerated concrete (SH perforated sleeve, W-VI-A anchor rod, W-VI-IG internal thread anchor, threaded rod with acceptance test certificate 3.1, autoclaved aerated concrete only without perforated sleeve)

- European Technical Assessment ETA-12/0166: Post-installed rebar connection, 330 ml, 420 ml and 825 ml cartridges only

- EPD: Environmental product declaration in accordance with ISO 14025 and EN 15804+A2, EPD-AWU-20230406-CBA3

- Anchoring in cracked and uncracked concrete, masonry laid with solid and perforated block, autoclaved aerated concrete and for post-installed rebars.

- Suitable for mounting metal structures, metal sections, wooden structures, brackets, grates, pipes, cable conduits etc.

A 330 ml and 420 ml cartridge can continue to be used until the best before date, by changing the mixer nozzle or resealing it with the end cap.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!