Joist bracket

Beam bearer

BMBEAR-H90MM

Art.-no. 068135090

EAN 4024835148375

Register now and access our wide range of products

- Easy on-site installation thanks to mounting slot in joist bracket blade

- Sheet metal hot-dip galvanised on both sides (S250GD +Z275 (approx. 20 µm)), thickness 3.0 mm in line with EN 10327:2004

- Application in utilisation classes 1 and 2 in line with EN 1995:2013

ETA-09/0105

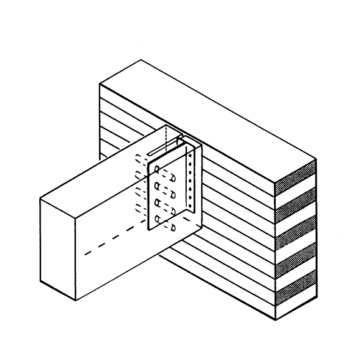

The secondary beam can be mounted on the joist bracket attached to the main beam after the first dowel pin has been driven in to the uppermost hole in the secondary beam. To do this, the secondary beam with the uppermost dowel pin mounted in the slot area is hooked into the blade area of the joist bracket from above.

The secondary beam should be approx. 40 mm taller than the joist bracket. If the bracket is 90 mm in height, a secondary beam 100 mm in height can be used.

The diameter of the dowel pin may only be max. 0.5 mm (d = 8 mm) or 1.0 mm (d = 12 mm) smaller than the diameter of the hole.

Available work documents:

Load tables and detailed installation instructions can be found on the service page www.wuerth.de/holzverbinder

ETA-09/0105

Subject to technical changes!

Datasheets(X)

Load-bearing connections of timber joists to timber main beams or posts in visible areas

Suitable fasteners:

- Ribbed nail in line with EN 14592: 4.0x40 mm

- Dowel pin in line with EN 14592, d = 8, 12 mm

| |

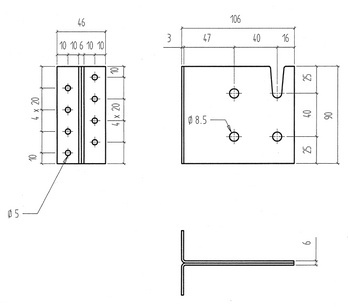

Width x height x depth | 46 x 90 x 106 mm |

Min. joist hanger height | 100 mm |

Hole diameter in subcarrier nJ/main carrier nH | 8.5 / 5 mm |

Number of holes in subcarrier nJ/main carrier nH | 3 / 8 PCS |

Weight | 470 g |

Approval | ETA-09/0105 |

Thickness | 3 mm |

Material | Steel |

Material designation | DX51D |

Material standard | DIN EN 10327:2004 |

Surface | Hot dip galvanized |