High-strength MBT blind stud, flat head

MBT blind stud dome head steel zn/steel zn

BLT-FL-ST/ST-(A2K/A2K)-(2-9,5)-6,5X14,2

Art.-no. 092165 95

EAN 4011231859240

Register now and access our wide range of products

- High-strength riveting range

- High, even preloading

- Positive and friction locking

- Completely vibration-proof

- Excellent fatigue properties

- High tensile and shear strength values enable connections for very highest loads

- Captive mandrel (mechanically locked)

- Safe filling of drill hole: airtight and splash-proof

- Exceptionally large clamping length range

- Quick installation with consistently high quality due to the use of the pneumatic device

May only be installed with lever riveting pliers (art. no. 0949810) or PNG 122 (art. no. 070393733) and matching nozzle (∅ 4.8 mm: art. no. 0946820 or ∅ 6.5 mm: art. no. 0946830).

Datasheets(X)

CAD data (available after login)

MBT blind studs are used for the production of high-strength, vibration-resistant and long-lasting connections under heavy mechanical loads. Designed for high tensile and shear loads, they are preferably used in the automotive and commercial vehicle industry, in mechanical engineering as well as in housing and switch cabinet construction. They are also used in heating, air conditioning and ventilation systems as well as in rail and vehicle construction. The application possibilities are very diverse, as the extraordinarily large clamping length range enables flexible use, while the positive and friction locking ensures even preloading and absolute vibration resistance.

| |

Material of sleeve | Steel |

Material of mandrel | Steel |

Surface of the mandrel | Zinc plated |

Surface of the sleeve | Zinc plated |

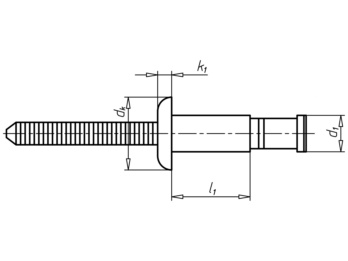

Nominal diameter x length (d1 x l1) | 6.5 x 14.2 mm |

Head diameter (dk) | 13.0 mm |

Head height (k1) | 2.5 mm |

Min./max. grip range | 2.0-9.5 mm |

Min./max. drill hole diameter | 6.6-7.0 mm |

Shear-fracture load | 11200 N |

Tensile fracture load | 8800 N |

RoHS-compliant | Yes |

Head type | Dome head |